Services

What We Do

External Wall Insulation

Silicone Texturing

Pebble Dash Rendering

Brick Effect Render

Through Colour Rendering

Sprayed Roughcast

Plastering and Dry Lining

Venetion Plastering

Get a Quote For Your Project

Through Colour Rendering

Over the years Weber have developed a specific product to satisfy all your requirements – “Monocouche”. Monocouche Renders represent a specific product that is weatherproof and through coloured. Carefully selected colours and aggregates make up the range of Monocouche Renders that produce a decorative finish that will mature naturally and blend with its surroundings, giving years of trouble-free service requiring minimal maintenance. Finishes: Scraped, scraped with ashlar joints, stone, or textured Colours: Available in three hundred shades of colour. Application: Spray applied Monocouche Renders offer the most highly efficient and cost-effective method of rendering large and modest areas. Smaller areas may be hand applied Advantages: Reductions in labour and time, allowing scaffold to be dismantled and ground works to begin earlier in the programme. Monocouche Renders offer genuine cost benefits over traditional methods.

Monocouche Render Systems is a manufacturer and supplier of through colour render systems providing high performance exterior coatings to support all methods of construction and renovation throughout the UK, Europe & Middle East.

Monocouche Render Systems is a manufacturer and supplier of through colour render systems providing high performance exterior coatings to support all methods of construction and renovation throughout the UK, Europe & Middle East.

With 20 years of investment in the development of through coloured render systems and their application Monocouche Render Systems are firmly placed to lead the external finishes market, constantly evolving, and adapting as new products and systems are required, we are at the forefront of material and render system development.

Currently serving the commercial, industrial & residential construction industries within the UK, Europe & Middle East our systems, unrivalled customer service and support is trusted and respected nation and worldwide.

Rendering in West Midlands

Having the total control of all system sales and their subsequent delivery means that we can track and oversee their application, where required supporting the end user to pass on the highest quality of finish and service to their respective clients.

Pebble Dash Rendering

Before the use of polymer cements in the 1990’s a pebble dashed finish could look tired and dull after several decades. Sublime Coatings is often called upon to rejuvenate such a property. With many coatings and rendering systems available we can find the right solution at an affordable price. It is possible to render onto pebbledash providing the substrate is in a good condition and the backing render is sound and solid. There are two main types of system available to render onto pebbledash. The first is a common type of render such as a lime render or polymer render which will produce a flat or scraped finish, the second is an acrylic or resin (or enamel) render, which will blend a certain level of the pebbles or spar out but still leave a nice textured finish. Both systems dramatically improve the look of any building and cover over the old, tired pebbledash Our Dashing Grade Aggregates are instantly recognisable by the coloured diamond bags. You can be sure you are purchasing top grade aggregate and gravel for your pebble dashing and dry dashing projects. Pebble dashing and dry dashing aggregates, washed and graded specifically for external building finishes. They give a decorative and long-lasting appearance. These are all packed in 25kg bags ready to apply.

Silicone Texturing

K-RendThin-coat Silicone renders are used as a contemporary finish to new-build applications and the re-modelling of existing facades in both render only and external wall insulation applications. High performing Silicone renders are highly water-repellent, vapour permeable and weather resistant. The silicone finish is available with a rolled texture in a wide range of colours. Performance: K-Rend with silicone technology for water resistance that works.

- Fully weather resistant whilst remaining vapour permeable

- Excellent durability and UV stable from a thin system build up

- Protects against damaging solvents, acids, and pollutants in the environment

- Low susceptibility to soiling

- Highly resistant to impact damage

- Manufactured from high quality silicone resin and UV resistant colour pigments

- Rated Class 0 for surface spread of flame when used as part of insulated systems

- Quality control compliance with DIN 18200

Brick Effect Render

Brick Effect Render is a versatile alternative to traditional brickwork. This is particularly ideal for use on projects where traditional new brickwork or brick slips are an impractical solution. How is Brick Effect Render done? Brick effect render is applied in two coats. Firstly, a wet-coloured base coat is applied followed by a complimentary coloured wet topcoat. A wide choice of colours is available. To create the Brick Effect, the topcoat is then cut through to expose the base coat ‘mortar’ layer, thus creating the brick effect finish. Brick Effect Render can be used on full elevations or simply as a method of adding an interesting detailing at building corners or window heads and is ideal for use on both render only projects and as a final finish for external wall insulation systems.

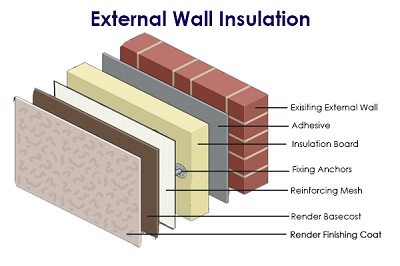

External Wall Insulation

To insulate a solid wall from the outside, a layer of insulation material is fixed to the walls with mechanical fixings and adhesive, then covered with protective layers of render or cladding. The finish can be smooth, textured or painted, tiled, panelled, pebble-dashed (for easy maintenance) or finished with brick slips to provide a real masonry brick finish. The finish will cover the whole of the outside of your property, including existing brickwork, and may change its appearance. So you must find out if you need planning permission: What about damp? Insulating the outside of your property, provided it is done properly, will give you a new weather proof layer that will protect you from penetrating damp for years to come, and should deal with any existing penetrating damp problems you may have had due to poor wall finish. The insulation will also increase the temperature of the internal surface of the wall, making it less likely that you will get condensation problems on your walls.

External Wall Insulation (EWI) systems by definition are applied to the exterior of a property, offering improved energy efficiency, weather protection and building aesthetics. They totally encapsulate the building structure which is the most effective way of insulating a building, with least risk of cold bridging and interstitial condensation.

What is External Wall Insulation?

An External Wall Insulation (EWI) system comprises rigid insulation boards fixed to the exterior walls of a property creating a ‘thermal jacket’, which are then over-coated with a weather protective, breathable, hard wearing, attractive render finish. This improves the building’s energy efficiency.

BENEFITS OF EXTERNAL WALL INSULATION (EWI)

Lowers Fuel Bills

High insulation levels achieved by the installation of an External Wall Insulation system result in savings on energy bills. An average solid wall semi-detached home could save around £475 per year on fuel costs (Source: Energy Savings Trust).

Prolongs Building Life

External Wall Insulation systems protect the building façade from the effects of the weather. Alumasc systems have an assessed minimum life of 30 years.

Improves Building Appearance

External Wall Insulation systems incorporate an extensive range of decorative finishes and colours ranging from modern silicone textured renders to traditional brick-effect finishes and many more in between.

Eliminates Condensation

External Wall Insulation helps eliminate interstitial and internal condensation and assists with overcoming associated problems such as damp internal walls and mould growth.

Minimises Disruption

By definition, External Wall Insulation systems are installed on the exterior of a building/property, therefore occupants do not have to leave their business premises or the comfort of their homes during the application of the system. In addition, internal space is not infringed upon

Plastering and Dry Lining

Sublime Coatings offer a professional plastering service for domestic and commercial purposes. Based in the West Midlands, we pride ourselves in being able to offer the highest standard of finish on all the projects we undertake. We offer competitive rates to all our customers no matter how big or small the job. In today’s housing market the finish on interior and exterior decor can have a big effect on the price and speed of house sales. Plastering may look simple but, as any DIY enthusiast will tell you, achieving a silky-smooth finish on walls and ceilings is impossible without years of practice. By letting us take care of your plastering work you are guaranteeing yourself a professional finish that can only serve to enhance your property. Sublime Coatings are a well-established and experienced Plastering and Drylining Company based in Wolverhampton. Our work includes major projects such as apartments, housing projects, public building developments as well as smaller prestige properties and individual commissions. We pride ourselves on delivering an extremely high standard of workmanship. With many years’ experience we have achieved a reputation for high quality work and ensure an excellent service from planning, costing, and quotation to project management of the job itself. We understand working in partnership with our clients is extremely important and ensure exceptional communication at all levels.

Lime Render

Lime renders were traditionally applied to give protection to walls built of poor-quality rubble stone or porous brick or to walls in exposed locations facing driving winds. They help by acting like a sponge, absorbing rainfall then allowing it to evaporate rather than soak into the wall. Most cottages and houses built of rubble stone would have been rendered originally and they tend to suffer from penetrating damp if the lime render is removed or replaced with a cement rich render. There is a very wide range of types of lime rendering. Rubble walls of many vernacular buildings were often treated with just a single coat of render, amounting to not much more than a very full, flush pointing. Such a render is thicker in the hollows and very thin over the stone faces. There was no attempt to create a flat surface so the undulations of the wall and even some of the stones themselves were not concealed. For a smarter finish or on more prestigious buildings the aim would be for a more uniform render achieved by applying a scratch coat to fill the hollows and take up some of the unevenness followed by one or two more coats which were worked to a flatter surface. Sometimes joint lines were ruled into the damp topcoat to create the illusion of ashlar stone, but a common finish for many houses and cottages was a rough cast where the final coat consisted of a mortar slurry containing coarse grit applied by throwing from a special trowel. For interiors, a smooth surface could be obtained using a coarse render mix, but for top quality internal plastering the final coat would be richer in lime and polished up to a smooth, close finish.

Renders and plasters can be applied to a variety of backgrounds including earth (which should always be rendered), stone and brick. Plaster is also applied to wooden laths for ceilings and internal partitions.

By carefully selecting appropriate aggregates it is possible to match existing renders and successfully repair failed patches without the need for complete re-rendering. Hollow or detached plaster can sometimes be consolidated and saved, and further advice should be sought before replacing it, especially if it is incredibly old.

Venetian Rendering

With its origins dating back to the first century in traditional Italian architecture. Beautiful luxury finishes can be created for a wide range of purposes in domestic, commercial, and retail properties, leaving a lasting effect that will add value to any building. Our skilled team can help you create a unique wall covering using bespoke colours and finishes for a contemporary or traditional finish. We use only the finest plasters imported from Italy, with a wide range of products with various application methods, techniques, and colours. Multiple products and colours can be used on the same wall to achieve a unique effect.

Sprayed Roughcast

Roughcast is a render with a coarse finishing coat containing gravel thrown in a premixed state onto a wall. It is distinct from pebble dash (or ‘dry dash’) in which the aggregate is applied separately onto wet plaster. Historically, roughcast was popular for rural buildings across much of the UK, except the south-eastern half of England. It was also sometimes employed for high status Arts and Crafts buildings. Compared to smooth render, roughcast is particularly advantageous in exposed districts because its heavy texture creates a larger surface area that aids moisture absorption and evaporation. Additionally, the application method allows use of a mortar mix less prone to shrinkage while curing.

What Mixes Are Suitable for Roughcast?

When patch-repairing, materials should be selected to ensure the existing roughcast is matched in strength and appearance, unless an inappropriate mix was used previously. In most cases, existing roughcast can be assessed from visual inspection coupled with local knowledge. Lime (not Portland cement), gravel and sand are typical ingredients suitable for use on a pre-1800 building but other constituents might include, for example, earth, stone dust, or brick dust. Hair is sometimes added to the underlying coat(s). The more water used in the finishing coat, the less heavily textured it tends to be. When not replicating an existing mix, new roughcast must consider site exposure and the strength and condition of the wall below.

How Is Roughcast Applied?

Before applying new roughcast, remove detached render beyond saving. Loose edges repeatedly dampened become sufficiently pliable to resecure with lime slurry grout (and, if needed, screws and washers); the new finishing coat is ‘feathered’ over the reattached edges. It is unnecessary, in most cases, to rake out mortar joints, and always inadvisable to hack masonry faces, to provide a key for new roughcast. Several thin coats are better than one thick one. The underlying coat(s), as well as the finishing coat, may be roughcast, rather than laid on smooth, if preferred. Roughcast can be machine-applied but hand-casting is as quick for an average-sized house. One method is to throw the mix ‘backhand’ from a casting (‘dashing’) float or cut-down coal shovel. The texture can be modified by wet or dry brushing as the surface firms up. Allow for weather protection.

Latest Projects

Project Title

Project Title

Project Title

m

Contact Us

Sublime Coatings Contact Form

Address

Sublime Coatings,

Unit 20, Purbrook Road

Wolverhampton,

WV1 2EJ